GSH2540 small portable jaw crusher and screening machine is used for crushing and sieving concrete aggregates, etc.

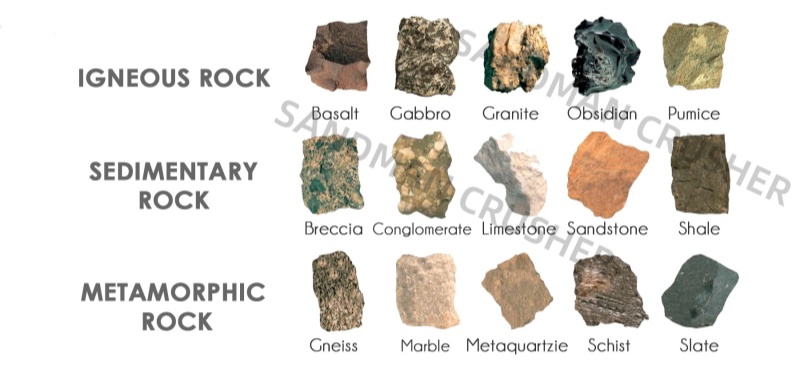

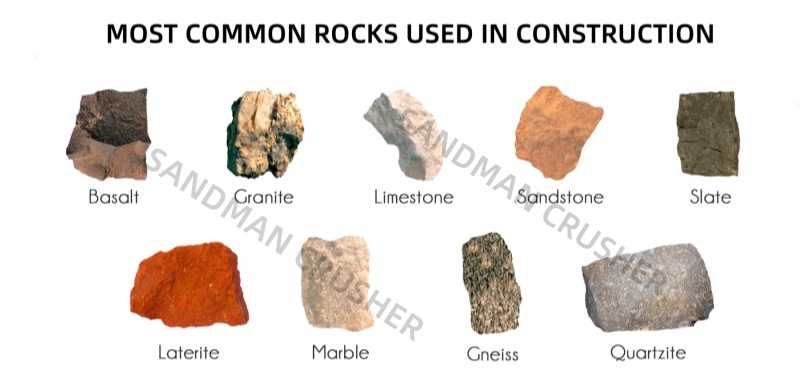

Suitable materials: Granite, marble, basalt, limestone, quartz stone, river pebbles, iron ore, copper ore, demolition, glass, waste bricks,etc.

Sandman Crusher features a simple engineering design to offer the industry the lowest cost to start your quarry business.

Introduction

The GSH2540 small mobile crushing plant is a versatile and efficient aggregate crushing solution suitable for various projects, especially small-scale crushing projects. This compact crushing plant is easily transportable. It integrates feeding, crushing, and screening and conveyoring functions, ALL IN ONE! If you have a limited budget and need mobility, this small mobile crushing plant is your best choice. You can use it for small-scale mining and quarrying operations, as well as small-scale construction, road and building demolition projects. It can also be used for crushing pebbles, granite, etc., for building construction. Whether you need to crush hard rock, recycle construction waste, or produce aggregate, this crushing system can help you complete tasks efficiently in a short time.

Overview

GSH2540 small portable jaw crusher and screening machine is used for crushing concrete stones, etc. Whether it is recycling concrete or asphalt, producing base aggregate, decorative rock, granite countertop scrap, recycling glass, slag, etc. the applications and income-producing possibilities of our sandman crusher are endless.This machine includes a hopper feeder so that you can load raw material by a small to medium-sized excavator and wheel loader.This small portable jaw crusher is tire-mounted for easy use.Powered by a 50Kw Weichai diesel engine generator. It Consumes about 8-13 liters per hour and has a 50L fuel capacity.Jaw crusher jaw opening size is 250*400mm, and suggested material input size is <210mm, or smaller in all directions.8-35 tons per hour capacity, it has adjustable output size from 20-80mm max.(for reference, at the tightest jaw setting of 20mm, you will get 8 tons per hour; whereas at the largest jaw setting at 80mm, you will get 35 tons. The average capacity is about 10-25 tons per hour. (The specific output is affected by many factors, such as the hardness of the stone, the water content of the stone, the size of the feed, the smoothness of the discharge)

|  |

Applications of the small mobile crusher

1. Mining and aggregate production: This small mobile crushing plant can crush hard rocks such as granite, basalt, limestone, and pebbles. The crushed aggregate can be used for concrete production. It is ideal for small quarries or temporary mines.

2. Construction and demolition waste recycling: Concrete waste, brick and stone waste, reinforced concrete, etc., can all be crushed using this small mobile crusher. Mobile crushing plants help you process these wastes on-site, reducing transportation costs and landfill volume.

|  |

3. River and Environmental Cleanup: You can use our small crushing plants to process large waste rocks in rivers for easier disposal or reuse.

4. Mine Tailings and Slag Treatment: Mine tailings can be crushed on-site to reduce volume. This facilitates waste reuse. Its mobility is particularly noteworthy; you can flexibly move the entire crushing equipment next to slag heaps for immediate crushing.

Whether you are a contractor, mining company, construction enterprise, or environmental cleanup team, this small mobile crusher offers a fast return on investment, flexible deployment options, and reliable performance.

Crushing Equipment Workflow:

| 1. Feeding - We use a hopper feeder to ensure a uniform and continuous flow of material into the crusher, avoiding blockages or overloading, effectively improving crushing efficiency and equipment lifespan. For feed sizes within 150mm, you will need to configure a small loader or mini excavator. |  |

2. Crushing - Efficiently Reduces Aggregate Size This crushing plant primarily uses a jaw crusher for crushing. You can use it to crush hard rocks such as granite, basalt, limestone, and pebbles. It is reliable in operation and has low maintenance costs. Typically, it can produce 8 to 20 tons of concrete-grade aggregate per hour. |  |

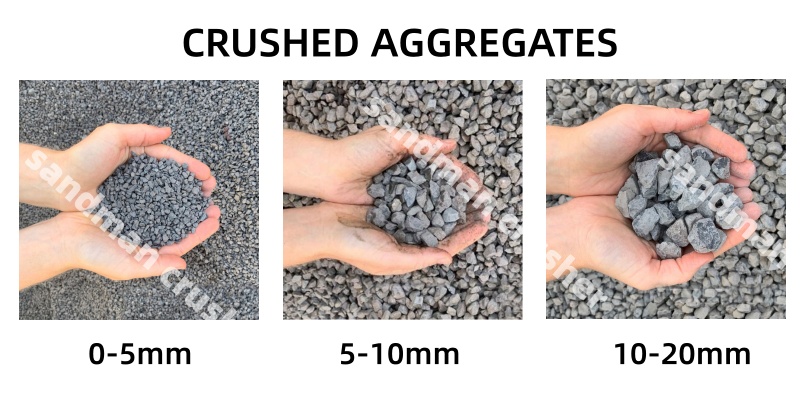

| 3. Screening – Precise Material Screening: The screening section uses a multi-layer vibrating screen to classify the crushed material according to different particle sizes. This screening machine can be used in various applications, such as building aggregates, roadbed materials, and mineral processing. It is highly efficient, with output sizes of 0-5mm, 5-10mm, and 10-20mm, adjustable (please contact the manufacturer for factory settings) to meet the needs of different users, and features stable vibration. The processing capacity is approximately 10 tons per hour to 50 tons per hour. |

|

| 4. Conveying – Continuous and Efficient Material Transfer: The entire machine is equipped with a complete conveyor system to classify and stack the screened materials, forming an automated production line and significantly increasing overall capacity. |  |

Technical Parameters

| Model: | GSH2540 |

| Processing capacity(US t/h): | 10-20 |

| Max. feeding size(mm): | 250 |

Final aggregates size(mm): | 0-5,5-10,10-20(3 types, Adjustable discharging sizes) |

Power supply unit: | Diesel generator-electric |

Generator power (kw): | 50 |

Oil consumption(L/h): | 10 |

Fuel tank capacity(L): | 50 |

Total weight approx. (kgs): | 13500 |

Overall size(LxWxH)(mm): | 10000x2490x3850 |

| Configuration: | Hopper vibrating feeder, Jaw crusher, Vibrating screen, Feeding/Crushing/Screening/Conveyor outlets, Conveyor belts (B500*7m,B500*3m,B500*9m,B500*9m), Motors,Control panel,Generator set,Mobile shelf assembly chassis |

Note: Technical data are subject to change without prior notice.

Why Choose This Small Mobile Crushing Plant? What are its Advantages?

This small mobile crushing plant is designed to achieve maximum flexibility, rapid deployment, and reduced costs. "Small but perfectly formed," this mini crusher integrates feeding, crushing, screening, and conveying into a compact, all-in-one unit. For your small crushing projects, it offers modular customization, independent power supply, and flexible mobility. It's ideal for construction, mining, recycling, and environmental projects.

1. Simple and standardized operation, clear button labels, and a rational layout: Upon arrival on site, production can begin with simple button operation. No complex training is required; even beginners can quickly operate independently.

2. High mobility and integrated design for maximum flexibility: Its compact layout allows it to adapt to confined urban spaces or rugged mining areas. This mini crusher can crush materials on-site, reducing transportation costs by at least 30% compared to traditional methods. Furthermore, it helps reduce waste disposal costs. You can recycle construction waste, tailings, and river stones into usable materials. They are ideal for space-constrained or small-scale projects.

3. Quick installation and short installation cycle: You can get it up and running within hours. It's also worth mentioning that you don't need to do extensive on-site installation work. We assemble all components before packaging. Simply connect the power supply to begin crushing operations.

4. Rapid Deployment, Zero Infrastructure Costs: The integrated wheeled chassis allows for rapid installation without concrete foundations or anchoring. Furthermore, it can be quickly moved between different work sites without disassembly, enabling immediate relocation. Operation can be completed within one hour. This maximizes productivity and minimizes downtime.

5. Self-Sufficient Power System: Powered by a diesel generator set, the equipment can operate in remote areas without grid coverage, significantly improving efficiency.

6. Optimized Transportation Costs: Its compact layout makes it suitable for cities with limited space or rugged mining areas. The mini crusher can crush on-site, reducing transportation costs by at least 30% compared to traditional transportation. It also helps reduce waste disposal costs, allowing you to recycle construction waste, mine tailings, and river pebbles into usable materials.

7. Low Investment, Quick Return: This mini crusher is known for its low investment threshold and short payback period. It requires no large capital commitment, making it affordable for small and medium-sized businesses, individual contractors, and small builders, making it the best choice for low-cost entrepreneurship. The equipment is inexpensive and affordable, with a fully automated crushing and screening system integrating feeding, crushing, screening, and conveying available for just US$30000-$40,000. The payback period is short, with returns possible within a few months. The equipment can be used for over a decade, and its resale and rental value is high. Minimal investment is required, eliminating the need for concrete foundations or fixed plant buildings. Labor costs are extremely low, and operation is simple and easy to learn; one person can manage equipment start-up, shutdown, feeding, and crushing control, eliminating the need for a dedicated operating team.

Contact: Hebe Wang

Phone: +86 150 9289 4665

Tel: +86 150 9289 4665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat