Jaw Crusher Routine Maintenance Essentials

Shanman jaw crushers are commonly used equipment in the mining, construction, and aggregate production industries, renowned for their powerful ability to crush hard and abrasive materials. However, because jaw crushers operate continuously under harsh conditions, routine maintenance is not just a routine task, but a critical investment to extend equipment life, reduce downtime, and ensure operational safety. This article will delve into the core aspects of jaw crusher routine maintenance, providing practical and easy-to-follow steps suitable for both experienced technicians and industry newcomers.

Understanding the Importance of Routine Maintenance

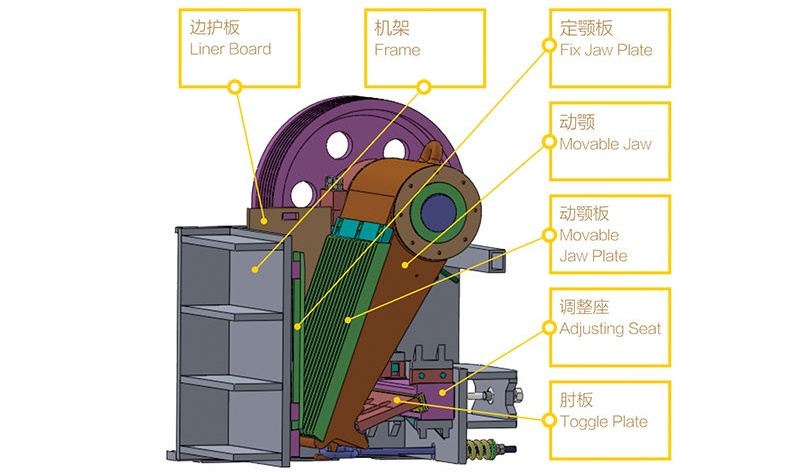

Before diving into the specific details, it is crucial to understand the importance of routine maintenance. Jaw crushers operate under high pressure and heavy loads, with components such as the toggle plate, jaw plate, and bearings subjected to continuous friction and impact. Neglecting regular inspections can lead to premature wear, unexpected failures, and even safety hazards. Studies show that a well-maintained jaw crusher can increase production efficiency by 15-20% and extend service life by 30% or more. For businesses, this translates to lower maintenance costs, more stable output, and stronger profitability.

Pre-Run Checklist

The first step in effective routine maintenance is to conduct a comprehensive pre-run check. This proactive approach helps identify potential problems before they escalate into major failures.

1. Visual Inspection of Critical Components

First, conduct a visual inspection of the entire crusher assembly. Inspect the jaw plates for signs of wear, cracks, or loosening. Jaw plates are major wear parts; uneven or excessive wear can reduce crushing efficiency and damage other components. Check for gaps between the stationary and movable jaw plates, as this may indicate misalignment or wear.

Next, inspect the toggle plate, which plays a crucial role in transmitting crushing force. Inspect the toggle plate and its bearings for cracks, deformation, or excessive wear. The flywheel and pulleys should also be inspected for cracks, loose bolts, or abnormal wear. Ensure the V-belt is properly tensioned and shows no signs of wear or damage.

2. Lubrication System Inspection

Lubrication is the lifeline of a jaw crusher; it reduces friction between moving parts and prevents overheating. Before starting the crusher, check the lubricating oil level in the tank. The oil level should be within the appropriate range. If the oil level is too low, add the appropriate type of lubricating oil—do not mix different grades or types of lubricating oil.

Check for leaks in the oil pump, filter, and piping. Leaks in the lubrication system can lead to insufficient lubrication, severely damaging bearings and other moving parts.

3. Safety Device Verification

Safety is always paramount. Ensure all safety devices are installed and securely fastened. Check the emergency stop button to ensure it functions correctly and is easy to operate. Inspect the electrical system, including wiring, connectors, and switches, for signs of damage, overheating, or loose connections. Ensure the crusher is properly grounded to prevent electric shock.

Monitoring During Operation

Continuous monitoring is crucial after the crusher is put into operation to promptly detect any abnormalities.

1. Performance Observation

Closely monitor the crusher's operation. Monitor the feed rate to ensure it is within the crusher's processing capacity. Overfeeding can overload the crusher, reducing efficiency and causing potential damage. Observe the discharge size of the crushed material—any sudden changes in discharge size may indicate jaw plate wear or misalignment.

Pay attention for unusual noises, such as grinding, knocking, or screeching sounds. These noises may be caused by loose parts, worn bearings, or misalignment. Touch the crusher casing to check for excessive vibration, which may indicate an imbalance in the flywheel or pulleys, or worn bearings.

2. Temperature and Pressure Monitoring Regularly check the temperature of critical components such as bearings, motors, and lubricating oil. The normal operating temperature for bearings should be between 60-70°C; temperatures above 80°C indicate a problem. Use a temperature gun to measure the temperature accurately.

Monitor the oil pressure in the lubrication system. Low oil pressure may indicate a leak, oil pump failure, or a clogged filter. If the oil pressure is below the recommended value, stop the crusher immediately and investigate the cause.

Post-Operation Maintenance Tasks

After the crusher is shut down, perform the following maintenance tasks:

1. Cleaning Clean the crusher, removing residual material, dust, or debris. Use a brush or compressed air to clean the jaw plates, toggle plates, and other components. Remove any material accumulated inside the crusher casing, as this can cause corrosion or blockage. Clean the oil filter and replace it if clogged.

2. Component Tightening

Vibration during operation can cause bolts and fasteners to loosen over time. Inspect all bolts, nuts, and screws, and tighten them as needed. Pay special attention to the bolts securing the jaw plate, toggle plate, flywheel, and motor. Loose bolts can lead to misalignment, excessive vibration, and component damage.

3. Wear Parts Assessment

Assess the wear condition of critical components and replace them as necessary. Replace the jaw plate when its wear exceeds its limit. Inspect the toggle plate bearings; replace them if they show signs of wear or damage. Inspect the V-belts and replace any worn, cracked, or broken belts.

4. Lubrication System Maintenance

After cleaning, add lubricating oil to the recommended level. If the lubricating oil is contaminated or deteriorated, drain the old oil and replace it with new oil. Clean the oil tank and filter to ensure efficient lubrication system operation.

Common Problem Troubleshooting

Even with regular maintenance, jaw crushers may encounter common problems. Here are some quick troubleshooting tips.

1. Excessive Vibration

Excessive vibration may be caused by flywheel or pulley imbalance, loose components, or worn bearings. Check the balance of the flywheel and pulleys and tighten any loose bolts. Inspect the bearings and replace them if necessary.

2. Low Crushing Efficiency

Low crushing efficiency may be caused by worn jaw plates, incorrect feed size, or excessive feed. Replace worn jaw plates and adjust the feed.

Contact: Hebe Wang

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat