Jaw crushers and hammer crushers differ in structure, crushing effect, and application scenarios. The hammer stone crusher is good for fine crushing, while a jaw crusher is more suitable for primary coarse crushing.

1.The applicable ranges of a jaw crusher or a hammer crusher are quite different.

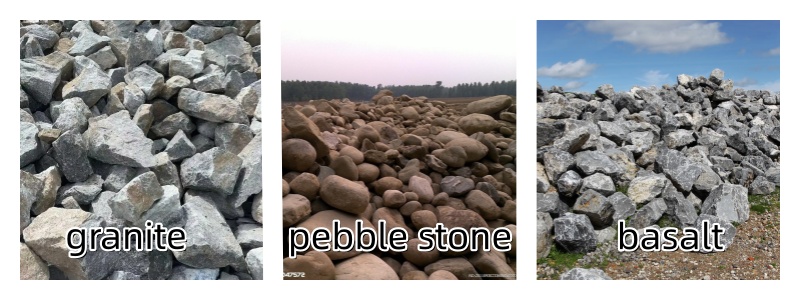

A jaw crusher is designed for high-hardness materials like granite, basalt, and iron ore, perfect for primary crushing of hard rocks.

The hammer stone crusher works well with medium and low-hardness materials such as limestone, coal, and construction waste. This hammer stone crusher is outstanding at crushing soft to medium-hard ores, widely used in building materials and coal industries.

2.The discharge effects of a jaw crusher or a hammer crusher are distinct.

A jaw crusher’s discharge is coarse with uneven particle size, mainly used for subsequent processing. The hammer stone crusher produces fine and uniform discharge, meeting direct application needs in construction and other fields. This hammer stone crusher can finish crushing in one time, reducing follow-up crushing steps.

3.The working principles of a jaw crusher or a hammer crusher are essentially different.

A jaw crusher uses the periodic movement of fixed and movable jaws to squeeze materials for crushing, with a slow speed but strong pressure.

The hammer stone crusher relies on high-speed rotating hammers to impact and strike materials. The hammer mill rock crusher’s hammers hit materials violently, making crushing efficient. This hammer stone crusher combines impact and crushing, suitable for fast material processing.

4.There are obvious differences in crushing granularity and output between a jaw crusher or a hammer crusher.

A jaw crusher has a large output, usually 1-1000t/h, and its discharge granularity is 10-300mm, fit for large-scale coarse crushing. The hammer stone crusher’s discharge granularity is 0-50mm, much finer than a jaw crusher.

The hammer mill rock crusher’s output ranges from 5-500t/h, lower than a jaw crusher but with better granularity. This hammer stone crusher balances fine granularity and stable output, suitable for medium-scale production.

5.The wear parts of a jaw crusher or a hammer crusher vary in type and service life.

A jaw crusher’s main wear parts are jaw plates, made of high-manganese steel, which are wear-resistant and durable, lasting 3-6 months. The hammer stone crusher’s key wear parts are hammers and liners. Hammers bear direct impact, wearing faster, with a service life of 1-3 months.

The hammer mill rock crusher’s hammers need regular replacement, but the replacement process is simple and low-cost.

6.A jaw crusher or a hammer crusher has its own advantages and disadvantages.

A jaw crusher has strong crushing capacity, good wear resistance, and long service life, but its discharge is coarse. The hammer stone crusher has high crushing efficiency, fine and uniform discharge, and a simple structure. However, the hammer stone crusher is not suitable for hard materials, and its hammers wear quickly. The hammer mill rock crusher is easy to maintain, but has poor adaptability to hard materials.

When choosing crushing equipment, you need to consider material hardness, required discharge granularity, output demand, and maintenance cost. For high-hardness materials and large output needs, a jaw crusher is the better choice. For medium-low hardness materials that require fine discharge, the hammer stone crusher is more suitable. The hammer mill rock crusher is cost-effective for small and medium-scale fine crushing projects. Considering your actual production needs helps select the right equipment, ensuring production efficiency and reducing costs. Choose a jaw crusher or a hammer crusher based on practical conditions to maximize equipment value.

Contact: Hebe Wang

Phone: +86 150 9289 4665

Tel: +86 150 9289 4665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat